Our SMT Solutions

At Haichen SMT, we understand that every production line is unique, with its own challenges and requirements. That’s why we offer tailored Surface Mount Technology (SMT) solutions designed to optimize your manufacturing processes, increase efficiency, and improve product quality. Our expert team works closely with you to identify the right combination of equipment, technologies, and processes to meet your specific needs.

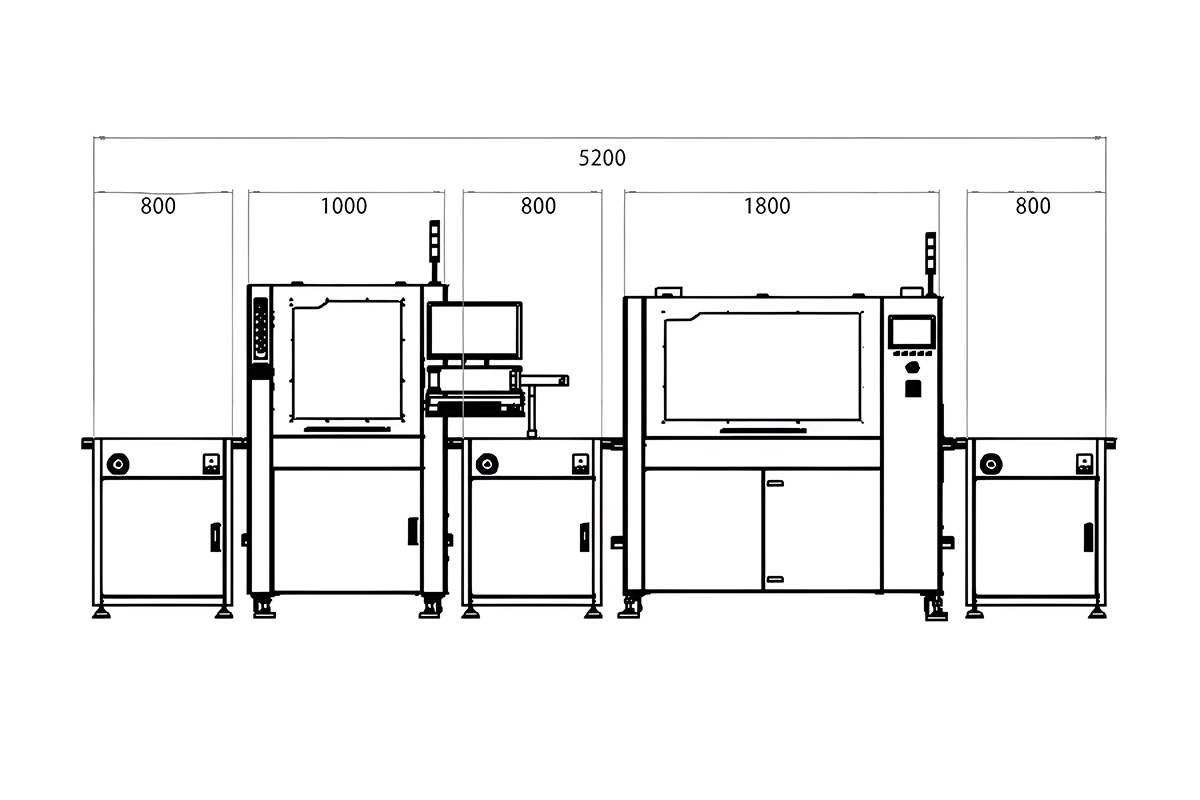

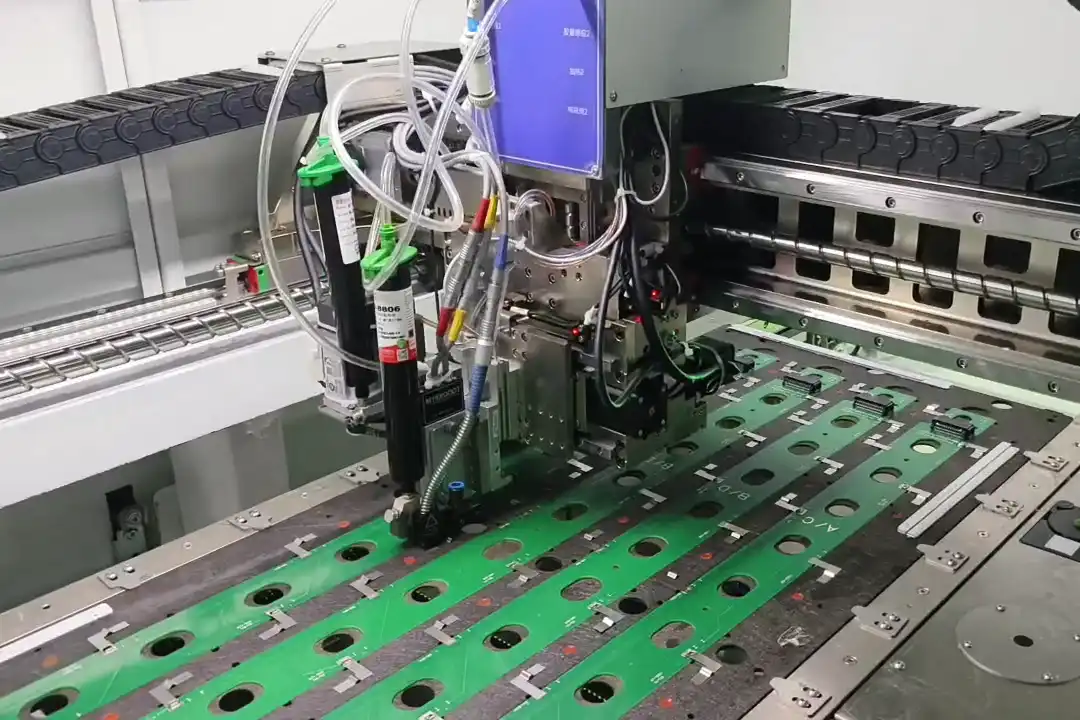

High-Speed Dispensing

Our high-speed dispensing solutions are designed to deliver precise application of adhesives, solder pastes, and other fluids at high speeds. Ideal for complex and high-volume production lines, our systems ensure consistent results, reduced waste, and increased throughput.

- Applications: Solder paste dispensing, adhesive application, underfill dispensing, and more.

- Benefits: Improved accuracy, reduced cycle time, and adaptable to various production environments.

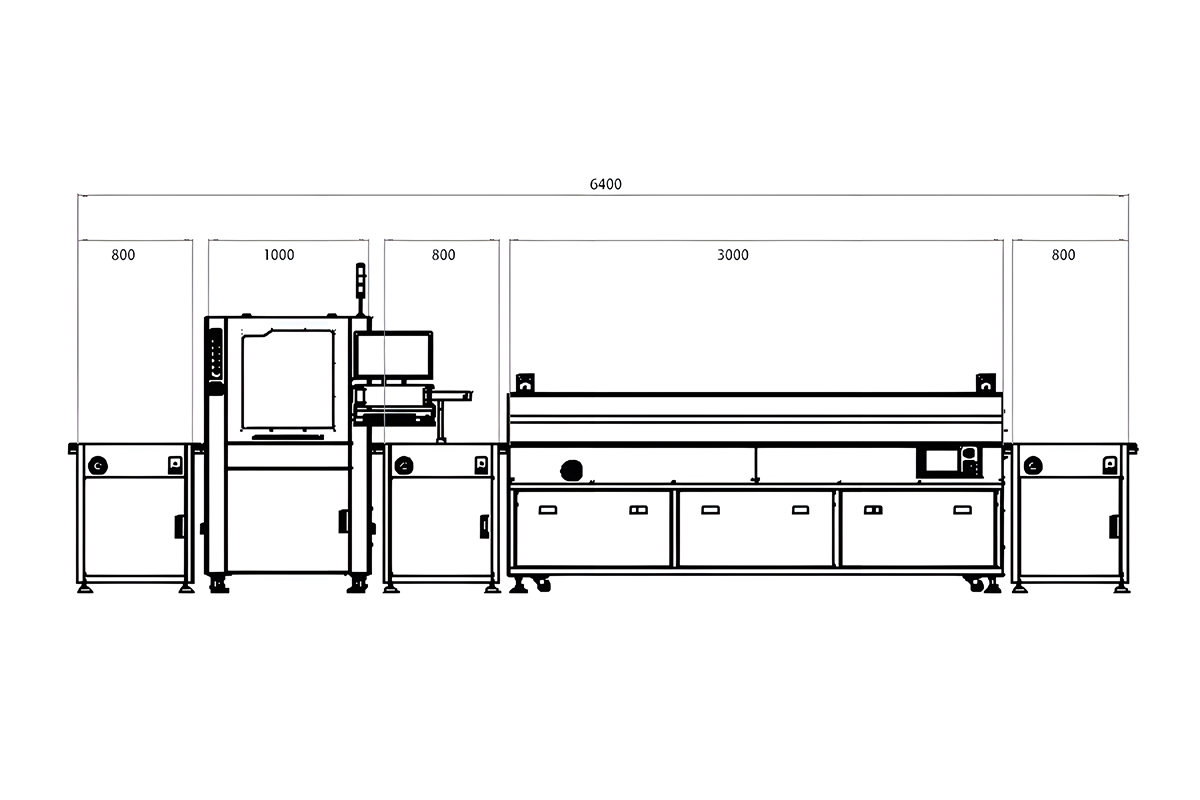

Selective Coating

Haichen SMT’s selective coating solutions provide precise application of conformal coatings, offering superior protection for electronic components against moisture, dust, and other contaminants. Our coating machines are highly customizable, allowing you to achieve optimal coverage for your specific products.

- Applications: Automotive electronics, consumer electronics, industrial controls, and more.

- Benefits: Enhanced reliability, reduced material waste, and user-friendly programming for complex designs.

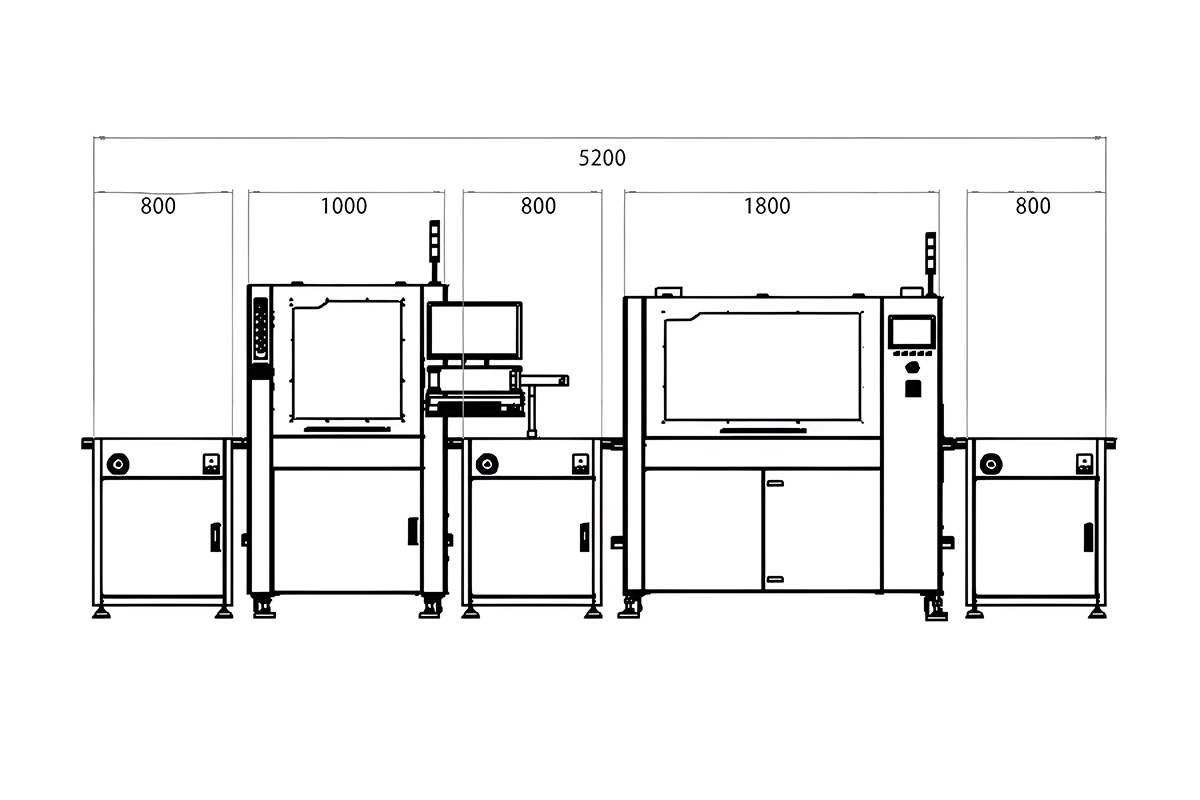

PCB Handling

Optimize your production flow with Haichen SMT’s range of PCB handling solutions, including lift machines, docking stations, and turning conveyors. These solutions are designed to streamline the movement of PCBs through your assembly line, minimizing manual handling and reducing the risk of damage.

- Applications: Automated PCB transfer between different stages of assembly.

- Benefits: Increased productivity, reduced handling time, and improved safety.

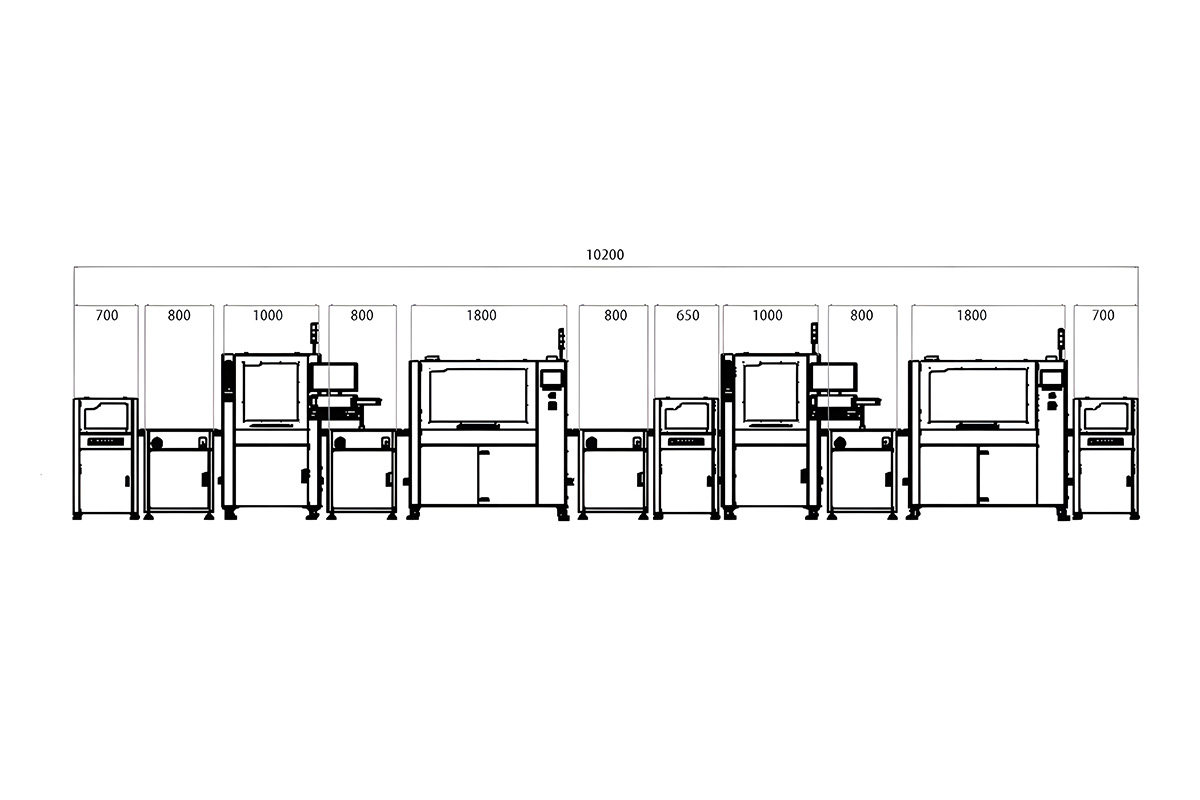

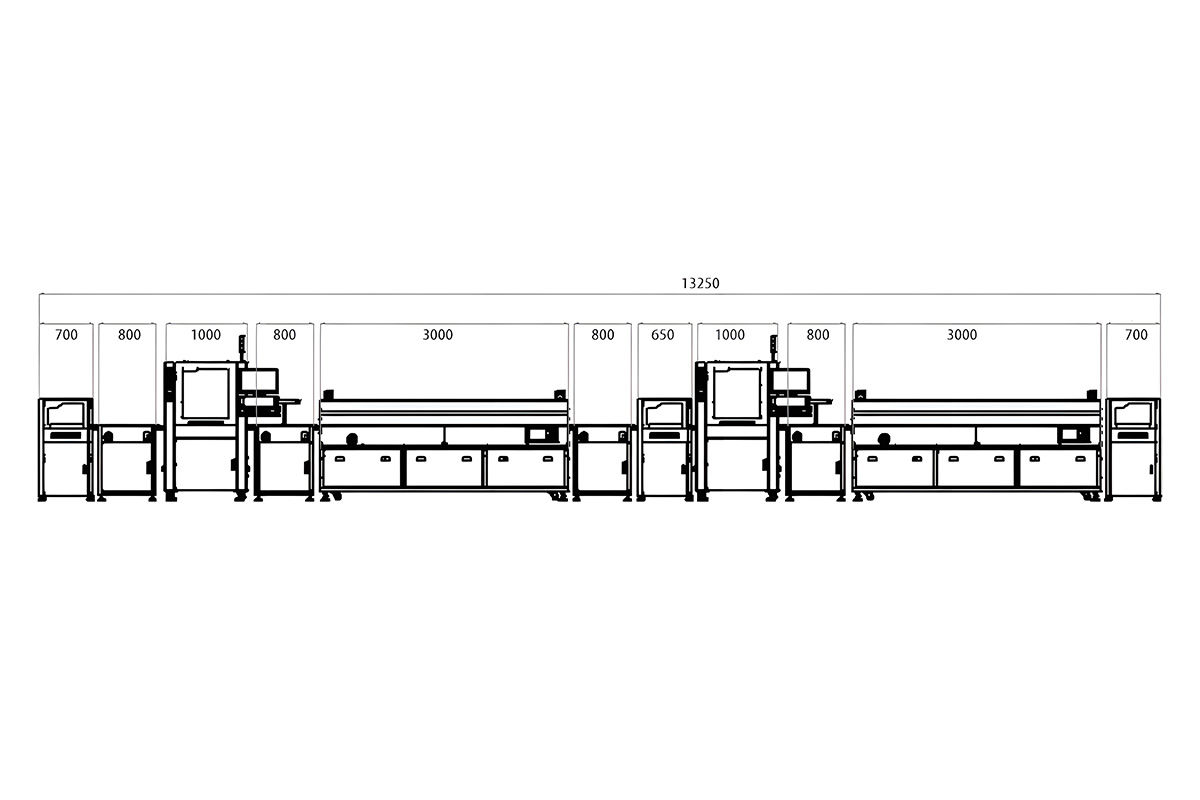

Customized Solutions

At Haichen SMT, we understand that each production environment has its own unique challenges. That’s why we offer customized solutions that are tailored to meet your specific requirements. Whether it’s modifying an existing machine, designing a custom dispensing pattern, or integrating our equipment into your production line, we have the expertise to deliver.

- Applications: Custom machine configurations, specialized fluid dispensing patterns, and more.

- Benefits: Fully optimized processes, better adaptation to complex requirements, and enhanced efficiency.

Our Process – How We Work with You

Consultation

We begin by understanding your production needs, challenges, and goals. Our experts work closely with you to evaluate your current processes and identify opportunities for improvement.

Solution Design

Based on your requirements, we design a tailored solution that incorporates the right mix of Haichen SMT equipment and technologies. We ensure that the proposed solution aligns with your production goals and budget.

Implementation

Our team supports you throughout the installation process, providing on-site assistance, training, and integration support. We ensure that your new equipment is up and running smoothly, minimizing downtime.

Ongoing Support

Our commitment doesn’t end with installation. We provide ongoing technical support, maintenance services, and training to ensure that your production line continues to operate at peak performance.

Why Choose Haichen

At Haichen SMT, we understand that choosing the right SMT equipment partner is crucial for your manufacturing success. As a leading provider of PCB coating and dispensing solutions, we combine technical expertise with customer-focused service to deliver exceptional value.

Expertise

With decades of experience in the SMT industry, we understand the challenges faced by PCB manufacturers.

Quality Guarantee

As an ISO certified company, We hold ourselves to the highest standards of quality, from product design and manufacturing to after-sales support.

Innovation

We strive to stay ahead of industry trends and deliver innovative products that help our customers lead in a competitive market.