Índice

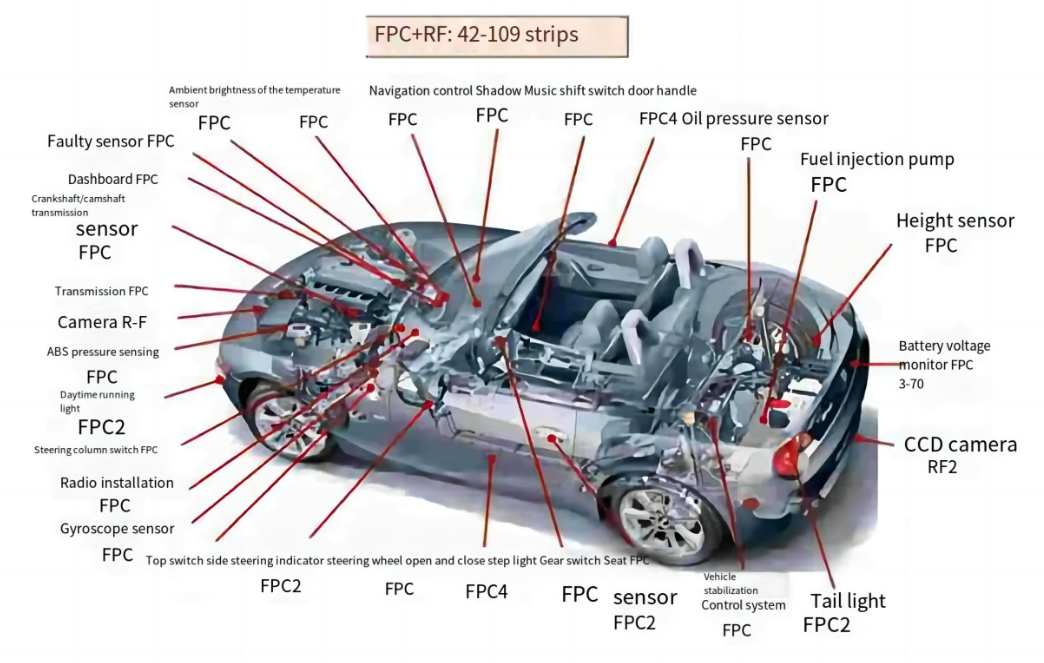

AlternarI. Análise do Setor (Por que precisamos de máquina dispensadora em produção)

II. O que é CCS?

![Solução de máquina de dosagem de alta precisão para pós-processamento de CCS em baterias de veículos elétricos 4 Teardown image of [product/model name] electronic module. Displays orange FPC interconnecting metallic cell - like components, critical for understanding internal design, component sourcing, and assembly process optimization.](https://haichensmt.com/wp-content/uploads/2025/06/CCS-1024x468.png)

Solução de Dispensação CCS (Caso Existente):

Solução de Dispensação CCS

- Cola UV

Aplicado principalmente em chapas de níquel sobre FPC para reforçar e proteger os pontos de solda. - Cola amarela

Utilizado para fixação de componentes eletrônicos como indutores, bobinas, transformadores, capacitores eletrolíticos e receptores, proporcionando proteção e vedação para as peças eletrônicas. Em sistemas de encapsulamento de circuitos integrados (CCS), é aplicado para encapsulamento de componentes elétricos, peças de alta tensão e revestimento à prova de umidade em circuitos integrados de baterias. - Silicone termicamente condutor

Projetado para preencher as lacunas entre componentes que geram calor e dispositivos de resfriamento, expandindo sua área de contato para aumentar a condutividade térmica. Isso dissipa o calor dos componentes eletrônicos de forma eficaz durante a operação. No CCS, ele atua como um material de interface térmica entre fontes de calor (transistores de potência, tiristores, elementos de aquecimento, etc.) e dispositivos de resfriamento (dissipadores de calor, fitas de resfriamento, invólucros, etc.), melhorando a eficiência da dissipação de calor. - Adesivo/Selante de Silicone

Adequado para encapsulamento, isolamento e retardamento de chamas em módulos eletrônicos, sensores e componentes, bem como para colagem/fixação de peças eletrônicas e isolamento entre componentes.

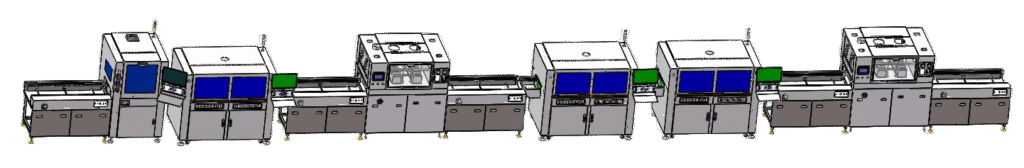

Visão geral:

Sistema de dosagem e enchimento da série HC-D1200S da HaichenSMT Destaca-se em aplicações de precisão e alta velocidade, apresentando métodos de dosagem quantitativa com e sem contato. Garante uma distribuição uniforme de cola e um corte preciso, eliminando defeitos como fios, volume irregular de adesivo e danos aos componentes. Este sistema aumenta significativamente a produtividade e a qualidade do produto. Equipado com módulos funcionais versáteis, oferece aplicações flexíveis e se destaca como a principal escolha para tarefas de dosagem e enchimento de precisão.

Aplicações:

Subterrâneo

Encapsulamento FPC

Conector FPC e Dispensação de Folha de Níquel

Dispensação de cola vermelha SMT

Encapsulamento de LED

Encapsulamento de componentes

Dispensação de pasta de solda

Dispensador de cola vermelha/preta

Impressão jato de tinta serigráfica de passo estreito

Embalagem de semicondutores

Fixação de wafers

Processo de trabalho: Carregamento das placas → Esteira transportadora para a área de trabalho → Posicionamento das placas → Alinhamento visual → Fotografia → Medição de altura Laser → Operação de dispensação → Descarregamento das placas