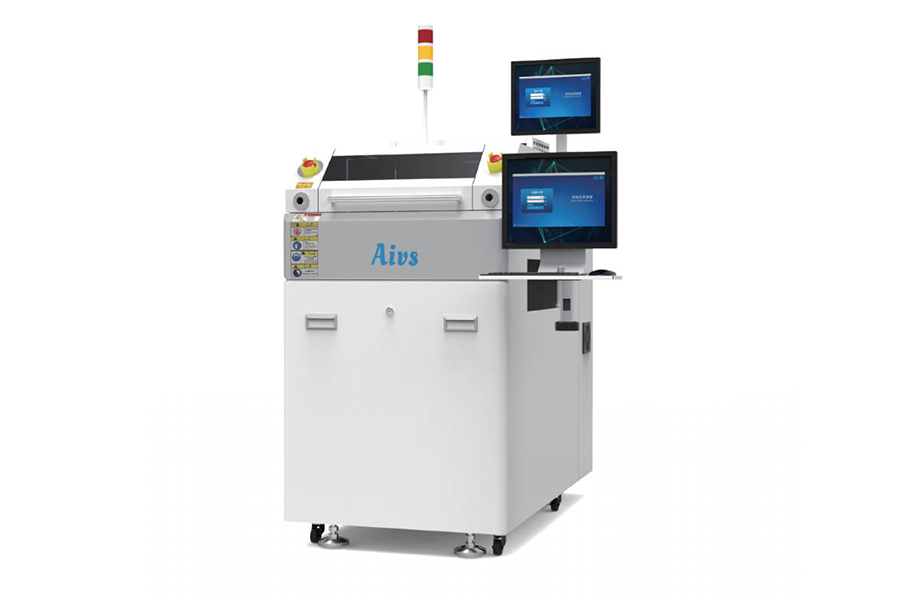

Selective Wave Soldering Machine

Our Selective Wave Soldering Machine offers a unique spray process for stable welding results, combining low cost with high flexibility. Engineered for efficiency, it’s designed to meet the demands of modern manufacturing with its compact size, automated features, and integration capabilities with AOI for online repair functions. Experience the next level of soldering technology with our Selective Wave Soldering Machine.

- Unique Spray Process for Consistent Quality

- Automated Nozzle Cleaning and Solder Level Control

- High Precision Spot Welding with Optional Heads

- Compact Design for Space-Efficient Workshops

- Integration-Ready with AOI for Enhanced Functionality

- Machine Size: L800W1400H1400mm

- Mechanical Pump Groove: φ3-12mm

- Wave Height Range: Max 5mm, Min 3mm

- PCB Gap: 2-8 mm

- Tin Furnace Capacity: 8KG

- Soldering Temperature Range: MAX 350℃, ±1℃

- Temperature Control Accuracy: ±1℃

- Heating Time: 40Min (at 300℃)

- Tin Furnace Power: 1KW

- Moving Speed: X/Y: 2 – 400 mm/s, Z: 2 – 50 mm/s

- Wave Accuracy: ±0.5mm

- Repeated Accuracy: ±0.05mm

- Spray Width: 130um

- Spray Nozzle Size: 2-8 mm

- Spray Method: Linear

- Pressure: 0.5Mpa

- Nitrogen Consumption: 1.5m/H

- Particle Cleanliness: ≥99.99%

- Nitrogen Preheating Temperature: MAX 350℃, ±1℃

- Process Visualization: CCD visible

- Data Import: Measure/Gerber, Images imported online

- Power: 3P5W, 380VAC, 50/60Hz

- Power Consumption: 4.5KW

- Air Supply: 0.5Mpa

- Optional Features: Automatic Solder Adding Device, Nozzle Automatic Cleaning Device, Spray Height Correction, AIVS Intelligent Manufacturing Platform Integration

Need Help Finding the Right Product?

Our team of experts is here to guide you in selecting the best solutions for your needs. Please feel free to reach us for support.