RZS12/15/20 Fully Automatic radial Insertion Machine

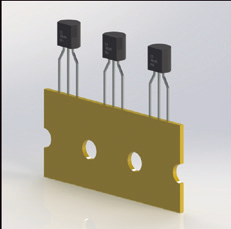

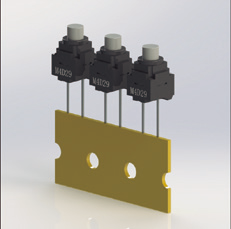

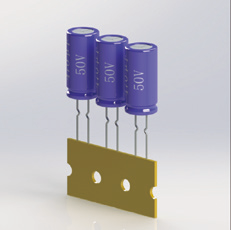

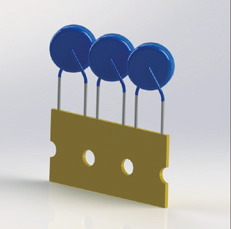

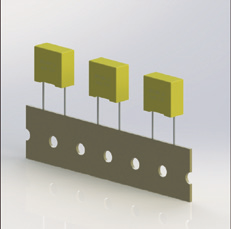

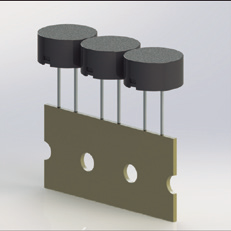

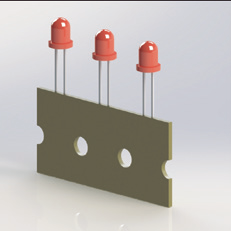

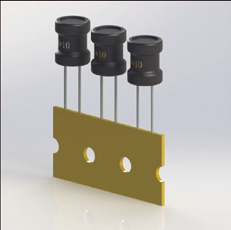

Specializing in the precise, efficient insertion of radial taped electronic components (capacitors, inductors, transistors, LEDs, tactile switches, radial resistors, connectors), the RZS series Automatic Radial Insertion Machine optimizes electronic assembly with exceptional speed and precision. Engineered for diverse radial tape packaging and high-volume production, it features advanced servo-driven mechanisms for stable feeding and accurate placement, plus an intuitive bilingual interface for easy operation. With customizable specs and robust defect detection, the series empowers manufacturers to boost productivity and minimize assembly errors.

- Compatible with all vertical taped materials

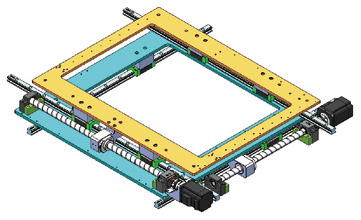

2. High-Precision Platform

0.01mm insertion accuracy,integrated ball screw modules &servo drive for high-speed and high-precision operation.

3. Optional High-Speed Cam Base

High-efficiency power system and intelligent dynamic control for high-speed,stable operation.Full-range dynamic adjustment for lead cutting.

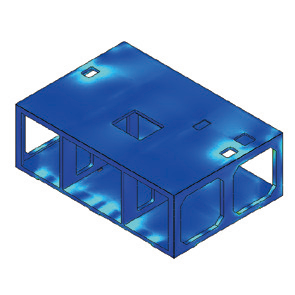

4. High-Strength Frame

One-piece ductile iron frame, 300-day natural aging &annealing,prevents thermal deformation.Superior vibration damping and tensile strength for long-term stability.

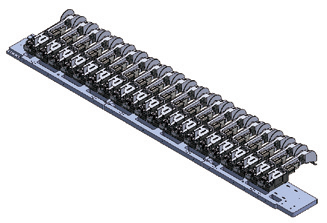

5. Hiah-Expandability Feeder Platform

Supports 80+ feeding units,covers 90%+industry components. High adaptability and worry-free configuration.

6.Fuxing Self-Developed Control System

Equipped with an industrial CCD positioning camera,Al-powered programming, full-process error-proofing,and assured high-efficiency production.

| 型号Model No | RZS 12 | RZS 15 | RZS 20 |

| 插装精度Insertion Accuracy | 0.01mm | ||

| 理论速度Theoretical Speed | 插件0.19秒/点,过板3秒/件, Insert 0.19 sec/pcs,transfer 3 sec/pcs | ||

| 供料器数量Feeder Number | 标配12支立式飞达 Std.radial feeder 12 sets | 标配15支立式飞达 Std.radial feeder 15 sets | 标配20支立式飞达 Std.radial feeder 20 sets |

| 插入方向&跨距 | 标准:-90°~+90°,360°可选,增量为1°,间距2.5/3.5/5.0/7.5/10.0mm(可选配) | ||

| Insertion Angle &Lead Pitch | Std.-90°to+90°,option 360°,increment in 1°;spacing option 2.5/3.5/5.0/7.5/10.0mm | ||

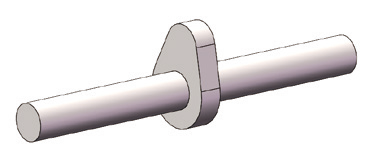

| 元件种类&规格 | 适用于立式编带封装料,编带孔距12.7/15mm;元件最大高度23mm,最大直径13mm,可定制 | ||

| Component Type&Size | Applicable to radial tape packaging Component,paper hole distance 12.7/15mm.Max.height 23mm.Max.diameter 13mm customizable | ||

| 元件引线剪脚长度 Component Lead Trimming Length | 1.2~2.2mm | ||

| 元件引线弯脚角度 Component Lead Bending Angle | 5~45° | ||

| PCB上下元件可通过高度 | 上23mm/下8mm | ||

| Passable Height of PCB Sides | Upper 23mm/lower 8mm | ||

| PCB尺寸PCB Size | 过板尺寸最大L500*W290mm,插件范围最大L415*W275m,左→右 | ||

| Max.PCB passing size L500*W290mm,Max.insertion range L415*W275mm,above L→R | |||

| PCB厚度&传送高度 | 厚度0.79~2.36mm,标准:1.6mm,高度900±20mm | ||

| PCB Thickness &Conveying Height | Thickness 0.79~2.36mm,std.1.6mm,height 900±20mm | ||

| 使用电源&功率Power Source | 220V,AC,50/60Hz,Apprx.约0.6KW | ||

| 使用气源&用气量Air Source | 0.6~0.8MPa,20m³/h | ||

| 使用环境温度Use Temp. | 10~26℃ | ||

| 设备噪音Mch.Noise | Apprx.约65dB | ||

| 设备重量Mch.Weight | Apprx.约1300kg,12站12 stations/约1450kg,15站15 stations/约1600kg,20站20 stations | ||

| 设备尺寸含供料器Machine Dimension | L1.76*W1.56*H1.6m,12站12 stations | ||

| L2.0*W1.56*H1.6m,15站15 stations | |||

| L2.5*W1.58*H1.6m,20站20 stations | |||

| 控制系统Control Sys. | Windows操作系统中英文界面、视窗平台、液晶显示 | ||

| Windows OS with Chinese/English Interface,Windows Platform,LCD Display | |||

| 驱动系统Drive Sys. | AC伺服,AC马达,AC servo,AC motor | ||

| 底座驱动方式Base Drive Mode | 电磁阀+精密气缸,凸轮机构+伺服电机,选配Solenoid valve +precision cylinder,cam mechanism+servo motor,optional | ||

| CTA送料方式CTA Feeding mode | 电磁阀+精密气缸,凸轮机构+伺服电机,选配Solenoid valve +precision cylinder,cam mechanism+servo motor,optional | ||

| PCB输送方式PCB Conveying Mode | 全自动:左→右,标准,右→左,选配Auto:std.L→R or option R→L | ||

| 数据输入方式Data Input Mode | USB接口输入, EXCEL文档格式, USB input,Excel format | ||

| PCB自动扫描系统 | 视觉系统自动采集PCB板图像,人机对话,可视操作 | ||

| PCB Auto Scan Sys. | Vision sys.auto capture PCB img.,human-machine interface &visual operation | ||

| Al智能编程系统 | 智能识别辅助编程,2分钟完成程序制作 | ||

| Al Intell.Programming Sys. | Intelligent recognition assist programming,2 min program create | ||

| Mark识别系统 | Mark识别算法自动补偿,解决PCB尺寸与坐标偏差 | ||

| Mark Recognition Sys. | Mark recognition algorithm automatic compensation,solve PCB size &coordinate deviation | ||

| 自动检测补件系统 | 自动识别插入不良,自动补插 | ||

| Auto Insertion Compensation Sys. | Automatic recognition the improper insertion,self-correct | ||

| Badmark识别系统 | 1秒内自动识别打X坏板并跳过,节省时间及物料 | ||

| Badmark Recognition Sys. | Automatic recognition&skip X-marked PCB in 1 sec,save time &component | ||

| 程序防呆系统 | 误操作修改程序坐标超出PCB范围,系统自动锁定停机并提示 | ||

| Prog.Foolproof Sys. | Misoperation modify programming coordinate out of PCB range,sys.auto lock,stop &alert | ||

| MES管理系统 | 实时上传共享生产数据,联动平台,辅助管理 | ||

| MES Mgt.Sys. | Upload and share production data in real-time,link with the platform for auxiliary management | ||

| 防错料系统 | 供料器二维码与物料条码导入系统自动比对, OK启动开机, NG报警停机 | ||

| Wrong Matl.Prev.Sys. | Feeder QR code &component barcode automatically comp.in sys,start if OK,alarm &stop if NG | ||

| 远程技术支持 | 专业工程师远程指导现场人员演示排查问题点,帮助解决技术问题或进行维护 | ||

| Remote Tech.Support | Prof.engr.remote guide site staff demo &troubleshoot,solve tech.prob.&maint | ||

Direct Sourcing & Full Product Range

- Partner with top-tier SMT equipment source factories with no middleman markup.

- One-stop coverage of full-range equipment and customized adaptations, eliminating the need to coordinate multiple suppliers.

Dual Expertise in Technology & Compliance

- Combine SMT technical proficiency with cross-border trade experience to accurately align with your process requirements and avoid communication gaps.

- Proactively ensure compliance with CE certification, regional voltage/protection standards, and smooth market access.

Transparent Process & Rapid Response

- Respond to inquiries within 4 hours; provide quotes + parameter sheets within 24 hours.

- Real-time tracking of production/logistics with proactive updates on key milestones. Flexible cooperation supported (e.g., trial orders, L/C payments).

Risk Mitigation & Reliable After-sales

- Professional pre-delivery quality inspection and customized shockproof/moisture-proof logistics packaging.

- 24/7 after-sales support with remote troubleshooting or on-site maintenance (in select regions). Single point of contact for efficient issue resolution.

Need Help Finding the Right Product?

Our team of experts is here to guide you in selecting the best solutions for your needs. Please feel free to reach us for support.