目次

トグル1. Pu1TP7トーセ

PCBA に UV 接着剤コンフォーマルコーティングを適用するためのプロセス フローと要件を確立して定義します。.

コーティング機の推奨:HC-P450S クリックして機械パラメータを表示

2. 範囲

当社全製品のPCBAコンフォーマルコーティングプロセスに適用可能です。.

3. コンテンツ

3.1 コーティングの準備

コーティングするPCBAの目視検査を実施してください。基板に明らかな指紋、汚れ、その他の外観上の欠陥がある場合は、洗浄剤で洗浄し、洗浄剤が完全に蒸発するまで待ってから次の工程に進んでください。.

3.2 スプレーできない部分の保護

3.2.1 保護対象部品

- ソケット、ピン、DIP スイッチ、ボタン、ノブ、再加工対象部品のパッドの両面、金属化されたネジ穴の両面、リベットナットの上端面および内面、端子台、ワイヤ端子、回路ブレーカー、IC ソケットおよび IC ソケットに組み込まれた IC、ブザー、LED (現在、SMD LED の部分塗装は基本的に明るさに影響しません)、LCD、バッテリー、その他特別に指定された部品 (各モデル専用のドキュメントによる)。.

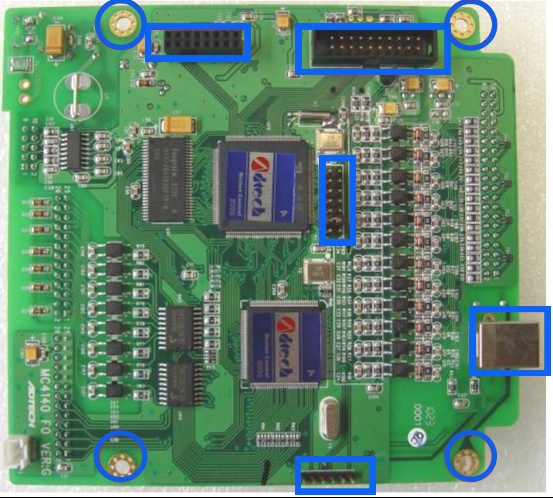

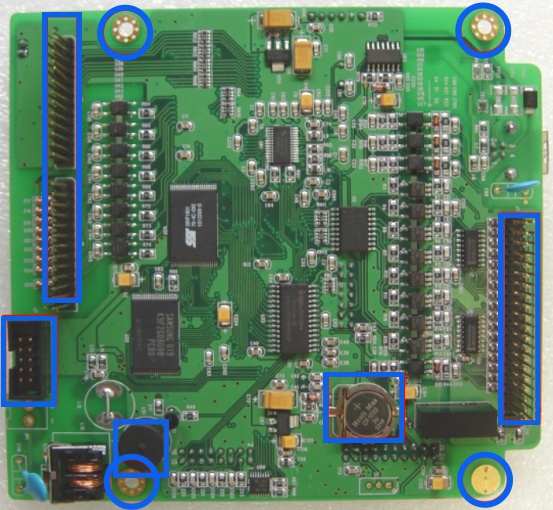

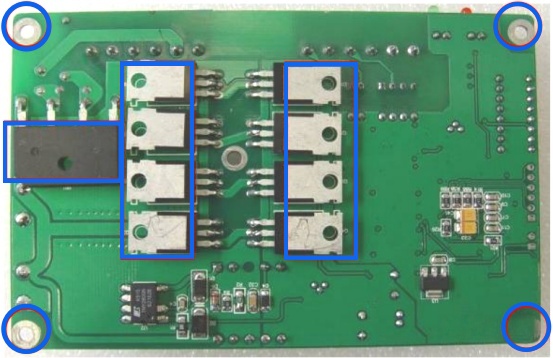

青枠内の部品はコンフォーマルコーティングでコーティングできません

青枠内の部品はコンフォーマルコーティングでコーティングできません

3.2.3 注意事項

- ツールに漏れや汚染がないか確認し、漏れや汚染がある場合は、ツールを脇に置いてすぐに報告してください。.

- 粘着テープ(またははんだ防止ペースト)を貼る際は、基板またはコンポーネント上の紙製バーコードを覆わないでください。.

- 粘着テープ(またははんだ防止ペースト)を貼り付けたり剥がしたりするときには、静電気防止リストストラップを着用してください。.

- コンポーネントが傾いたり落下したりしないように、操作中にボードを保護します。.

- 操作によって生じた欠陥のあるボードを分離してラベルを付けます。.

- 作業終了後、作業者は必ずボードの自己点検を行ってください。ボードを載せる際は、ボード間に約1cmの隙間を空け、搬送カートは両手で押してください。無理に押したり、カートを自由に転がしたりしないでください。.

- 硬化後、接着テープ(またははんだ防止ペースト)を剥がす際に紫外線ランプを使用して PCBA を目視検査し、スプレー漏れやテープ/ペーストで覆われた SMD コンポーネントがないか確認します。見つかった場合は、コーティングを補修します。.

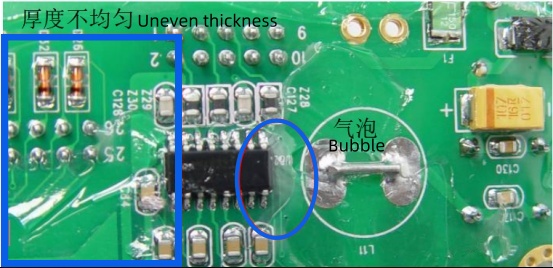

- 硬化後、紫外線ランプを使用して気泡、白斑、しわ、ひび割れ、剥がれ、汚染などの欠陥がないか目視検査し、問題があればすぐに監督者に報告してください。.

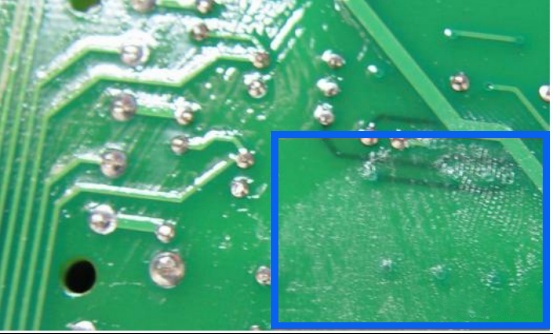

ブラッシング後に気泡が出て厚みが不均一になる

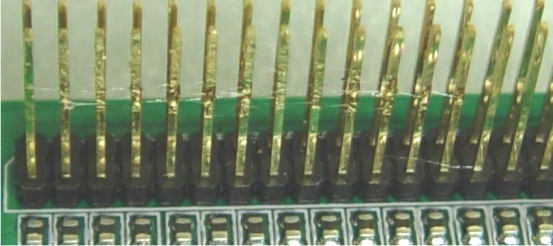

コンフォーマルコーティングで汚染された2列ピン

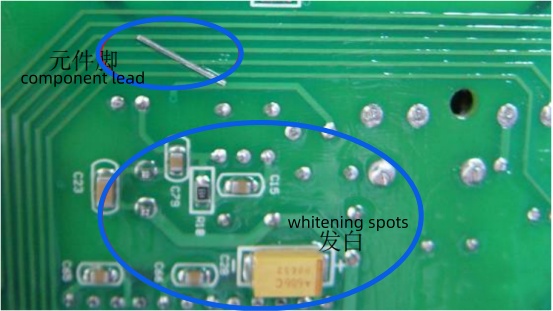

コンポーネントleadsとPCB表面の白化斑

PCBのコンフォーマルコーティングに波紋がある

PCB表面上の部品の部分的な濡れ

3.3 コーティング作業

3.3.1 オペレータ保護

オペレーターはマスクを着用し、可能であれば保護ゴーグルも着用する必要があります。.

3.3.2 エアパス排水

毎日使用する前に、午前と午後に 1 回ずつ、油水分離器貯蔵タンクから水を排出してください。.

3.3.3 コーティング混合

新しいコンフォーマルコーティング材料を準備する前に、まず圧力タンクの圧縮空気をオフにし、圧力リリーフバルブを開いてタンク内の圧力を解放し、次にスプレーガンのトリガーを引いてパイプライン内のコンフォーマルコーティングをバケットに戻します。最後に圧力タンクのカバーを開けて、指定された棚に置きます。.

2. 蛍光コンフォーマルコーティングの場合、コーティングとシンナーの混合比率は、スプレー装置と乾燥膜厚のテスト結果に応じて、体積比で 5:1 です。注: 同じバッチコードのコンフォーマルコーティングは、同じバッチの PCBA に使用する必要があり、混合は禁止されています。.

3. シンナーバケツの蓋を外し、計量カップに適量のシンナーを入れ、蓋を締め直して、計量したシンナーを噴霧タンクのステンレス製内バケツに注ぎます。使用済みのシンナーバケツは元の場所に戻します。.

4. コンフォーマルコーティングバケットの蓋を緩め、塗料をスプレータンクのステンレス製内バケツ(規定量のシンナーが既に入っている)に注ぎます。マーキングロッドを使って塗料量を測り、ロッド上部の熱収縮スリーブのすぐ下まで塗料が届くようにします。.

5. 加圧噴霧タンクに蓋をし、圧力リリーフバルブを閉じ、ミキシングハンドルを時計回りに10回、反時計回りに10回ゆっくりと振って、シンナーと塗料を均一に混ぜます。次に圧縮空気を投入し、タンク内圧が0.4±0.1kgf/cm²であることを確認します。塗料が均一に吐出されるまでトリガーを引き、配管内の圧力空気を解放します。.

3.3.4 コーティング

1.噴霧タンク内の圧力が0.4±0.1kgf/cm²であることを確認します。.

2. スプレーガンの圧力調整バルブを最大まで開き、ガンに接続された圧力ゲージを使用して圧力調整バルブを 3.0~4.0kgf/cm² (換算: 3.0~4.0kgf/cm² = 2.94~3.92 bar = 42.68~56.90 psi) に調整します。.

3. 基板全体にスプレーした後、ヒートシンク上のパワートランジスタの lead 領域などの重要な領域に追加のコーティングを施します。.

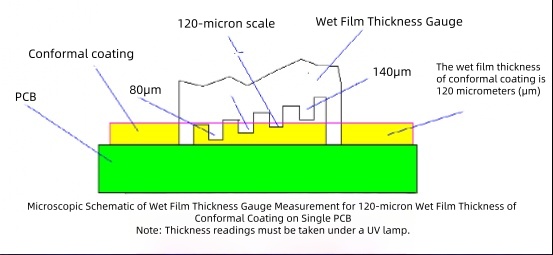

4.ガン後部のニードルバルブを使用して塗料流量を調整します。毎日の塗装を開始する前に、まず金属測定プレート(4.3.4.6に従って)に塗装し、次にウェットフィルム厚さゲージでウェットフィルムの厚さをテストして120ミクロン以上であることを確認し、「ウェットフィルム厚さテスト記録」に記録します。手塗りの場合は2時間に1回以上、自動塗装の場合は4時間に1回スポットチェックしてください。使用後は、金属プレートをシンナーに浸した布で、ウェットフィルムテスターをシンナーで清掃します。関係管理者はテスト記録を確認する必要があります。注:スプレーガンのオペレーターが変更された場合は、塗料の厚さを再テストします。図に示すように、測定領域が小さく、ボード上で直接測定するのに適しているため、測定にはスナップゲージを優先的に使用します。測定値は紫外線ランプの下で読み取ります。.

注:ウェット膜厚試験は誤差が大きいため、servesはプロセス管理の参考としてのみ使用してください。スプレー品質はドライ膜厚試験に基づいています。ディップコーティングやブラシコーティングではウェット膜厚試験は不要です。.

5. 塗装した PCBA を載せた移送カートを空気乾燥位置まで押します。.

6. PCBAの左上隅からスプレーを開始します。調整したパラメータ(厚さテストに使用)を使用して、スプレーガンを左から右へ均一な速度で水平に動かします。.

7. 自動スプレー塗布の場合は、図に示すように重ね塗り方式を採用してください。スプレーパターンのサイズと重ね塗りは、使用する機器に合わせて設定してください。基板全体にスプレー塗布した後、ヒートシンク上のパワートランジスタのlead領域など、重要な箇所に追加塗布してください。.

8.紫外線ランプの下でボードが均一にスプレーされているかどうかを検査し、不均一な部分があれば修正します。.

9. 手作業でスプレーした後、自然乾燥、自然乾燥、またはベーキングを行います。自動スプレーは通常、ベーキングラインに接続され、ベーキングを行います。フィルムは室温で3~5分で表面乾燥します。.

10. PCBAの両面スプレー塗布の原則は、まず背の高い部品がある面からスプレー塗布し、20分以上自然乾燥またはベーキングを行い、表面が乾燥していることを確認した後、PCBAを裏返して背の低い部品がある面にスプレー塗布することです。両面にSMD部品がある場合は、手作業でスプレー塗布する際に下向きの面を支え、部品がトレイに接触するのを防ぎます。.

11. スプレー後、スプレーガンを専用ラックに置き、ノズルをシンナーに浸してください。シンナーが不足している場合は、速やかに補充し、完全に浸るようにしてください。.

12.二次コーティング

標準外の手作業による薄層塗装では、塗膜品質に問題が生じる場合が多いため、高度な保護性能が求められる製品の手吹き/刷毛塗りでは、二次塗装が必須です。塗装方法は一次塗装と同じです。.

高保護製品の機械噴霧では、二次コーティングを行わずに、噴霧速度を調整するか、ノズル流量を増やして厚さ要件を満たします。.

13.二次ウェットフィルム厚さ試験

1回目の噴霧湿潤膜厚試験と同じ方法。.

14.二次フィルム表面乾燥

・手作業でスプレーした後、自然乾燥、自然乾燥、またはベーキングを行います。自動スプレーは通常、ライン上でベーキングを行います。表面乾燥後、製品はフィルムに衝突や摩擦なく転写できます。.

3.3.5 ブラシコーティング

1. コンフォーマルコーティング剤を入れるための適切な容器(例:使い捨て紙コップ)を用意します(手塗りの場合はシンナーは不要です)。塗布量(約2時間分)を超えないようにしてください。2時間以上空気に触れた液体は交換してください。使い捨てカップは再利用できません(他の容器は洗浄し、自然乾燥させて再利用できます)。.

2. ブラシコーティング用の柔らかいブラシを準備します(PCBのサイズに基づいて適切なサイズを選択し、エッジ部分や届きにくい場所には幅1cm以下の小さなブラシを使用してください)。ブラシは(シフトごとに)交換するか、毛が裂けたり飛散したりした場合はすぐに交換する必要があります(コーティング品質に影響を与えたり、対象領域外にコーティングするリスクがあります)。柔らかいブラシを適量のコンフォーマルコーティング剤(液だれしない程度)に浸し、PCB表面に対して45度の角度で、重ね塗りしながらブラシをかけます。気泡を防ぐため、同じ場所での繰り返しブラシは避けてください。液体がPCBとコンポーネントを完全に濡らすように、ゆっくりとブラシをかけてください。.

3. 紙コップで約 2 時間コーティングを塗布した後、カップを交換し、新たに 2 時間分の供給液を注ぎ、操作を続行します。.

4. 両面刷毛塗りの場合は、ボードを水平に置いて片面を刷毛塗りし、表面が乾くのを待ってからもう片面を刷毛塗りします(ボードは水平に置きます)。.

5.ランプボードや小型ボードでは一般的にブラシコーティングが使用されますが、大型ボードでは各モデル専用のドキュメントに従ってコンフォーマルコーティングマシンを使用することをお勧めします。.

3.3.6 硬化

1.コーティングラインではコンベア式硬化炉を使用しています。塗装と検査を終えたPCBAキャリアは、チェーンを介して硬化炉に搬送されます。専用のドキュメントに従って、炉の温度と硬化時間を設定してください。

2. キューイングの前にオーブン トラックを調整し (前のトラックと合わせる)、オーブンの温度とチェーン速度を設定します (速度が速いほど硬化時間が短くなります、vice はその逆です)。.

3. PCBA がオーブンから出てきた後、キャリアの端を両手で持ち、転送カートに載せて、換気の良い場所に押して空冷または室温で冷却します。.

4. オーブンを開けるときやキャリアを扱うときは、高温による火傷を防ぐため保護手袋を着用してください。.

3.4 コーティング検査、受入れ、および問題フィードバック

1. PCBAのコーティング、硬化、保護材の除去後、作業者は保護対象エリアの汚染を検査する必要があります。欠陥が見つかった場合は、その部分を脇に置き、ラベルを貼付して速やかに報告してください。.

2.完成した基板を搬送台車に積み込み、組立ラインまたは梱包ラインへ移動します。.

3.5 乾燥膜厚の試験と修復

1. 乾燥膜厚計を使用して、硬化および冷却されたコーティングされたボード上の乾燥膜厚を次のようにテストすることが望ましいです。

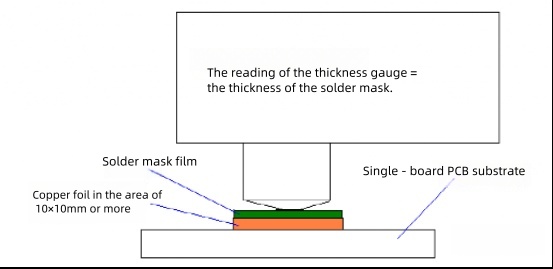

A. コーティング前に、基板上の10×10mmの銅箔領域を選択し、グリーンオイルの厚さをテストし、その値を記録します。ソルダーレジストはスクリーン印刷で塗布されるため、同一バッチのPCBでは厚さは一定です。図に示すように、PCBソルダーレジストの各バッチごとに厚さテストの記録を保持してください。.

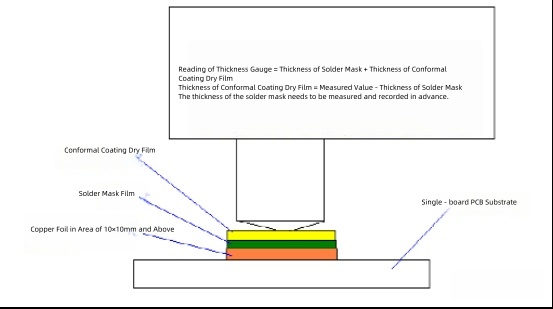

B. 硬化・冷却後のコーティング基板において、10×10mmの銅箔領域を選択し、絶縁材(ソルダーマスク+コンフォーマルコーティング)の厚さを測定し、その値を記録します。コンフォーマルコーティングの厚さ=この測定値-同じバッチのPCBのソルダーマスクの厚さ。注:この測定値は銅箔上の絶縁層の厚さであり、グリーンオイル+コンフォーマルコーティングの厚さに相当します。測定された乾燥膜厚がSOP要件を超える場合、湿ったコンフォーマルコーティングが非コーティング部品を汚染するリスクがあります。速やかにMEエンジニアに報告し、スプレーガンの流量を調整してください。流量超過の機械が非コーティング部品を汚染している場合は、修理または交換してください。汚染されていない場合は、機械は正常な製品を生産できます。.

塗布において、基板上で厚さを測定できない場合は、PCBAを塗布するトレイにアルミサンプルプレート(前述の金属測定プレート)を設置します。硬化・冷却後、厚さ計を用いてアルミプレート上の乾燥膜厚を測定します。.

要件:

A. 保護力の高い製品の場合は、専用文書に従ってスプレーしてください(通常、厚さは 50 ミクロン以上)。.

B. 一般製品の場合、厚さは30ミクロン以上が一般的です。手塗りの場合は少なくとも4時間ごとに1回、自動塗装の場合は8時間ごとに1回テストを実施してください。.

2. ディップコーティング:アルミニウムサンプルプレートをコンフォーマルコーティング剤に5秒間浸漬し、その後取り出して硬化させます。スプレーコーティングと同様の条件で、アルミニウムプレート上の乾燥膜厚を測定します。.

3. ブラシコーティング: 通常の操作に従ってアルミニウムサンプルプレートにコンフォーマルコーティングをブラシで塗布し、硬化させて、スプレー塗装と同じ要件で乾燥フィルムの厚さをテストします。.

4. 湿潤膜厚試験は誤差が大きく、serves はプロセス制御の基準としてのみ使用されます。スプレー品質は乾燥膜厚に基づきます。.

5.乾燥膜厚を直接試験できるボードの場合は、ボード試験データを基準とします。.

4.6 部品の交換とフィルムの修復

フィルムコーティングと硬化後にコンポーネントを交換する必要がある場合は、次の手順に従ってください。

1.はんだごてを使用して通常通り部品のはんだを除去し、その後シンナーに浸した布でパッドの周囲に付着した黄ばんだ物質を拭き取ります。.

2. はんだごてではんだ除去が難しい場合は、まずシンナーに浸した綿棒でパッドのコンフォーマルコーティングをこすり、部分的に溶解または薄めてから、はんだごてでコンポーネントのはんだ除去を行い、シンナーに浸した布でパッドの周囲を清掃します。.

3.交換部品をはんだ付けします。.

4.はんだ付け部分にコーティング剤を塗布し、フィルム表面を硬化させます。.

4.7 コンフォーマルコーティングの使用上の注意

1.塗装室(ライン)で作業する際は、塗装機、オーブン、その他の機器の操作ガイドラインを厳守してください。必要に応じて機器の保守・点検を行い、静電気防止手袋を着用してください。.

2.コンフォーマルコーティングとシンナーの混合比率に注意してください。.

3. コンフォーマルコーティング剤とシンナーを使用した後は、バケツの蓋をしっかりと閉め、30℃以下の換気の良い日陰の場所に保管してください。火気、電源、電磁干渉源から遠ざけてください。保管棚は必ず接地してください。.

4.ご使用前に製造日を確認し、期限切れの製品は使用しないでください。.

5. コンフォーマルコーティングが皮膚に付着した場合は、直ちに石鹸または洗剤で洗い流してください。飲み込んだ場合は、直ちに医師の診察を受けてください。目に入った場合は、こすらずに直ちに水で洗い流し、速やかに医師の診察を受けてください。.

6. 24時間ごとにスプレーした後、スプレーガンの塗料入口パイプを外し、硬化物の詰まりを防ぐため、シンナーを10回以上スプレーしてください。ガンヘッドは毎週分解して洗浄し、ノズルと調整ネジを徹底的に洗浄してください。ニードルバルブは損傷を防ぐため、他の部品と一緒に洗浄しないでください。また、ニードルバルブで物を突かないでください。12時間以上使用しない場合は、スプレーガンを徹底的に洗浄してください。刷毛塗り用具は毎日シンナーで洗浄し、廃液は密閉式のプラスチックバケツに回収してください。環境保護のため、無造作に廃棄しないでください。.

7. 塗装用の空バケツはすべてしっかりと締め、指定された場所に置いてください。空バケツ、残渣、廃液は専門の廃棄物処理業者に処分を依頼してください。.