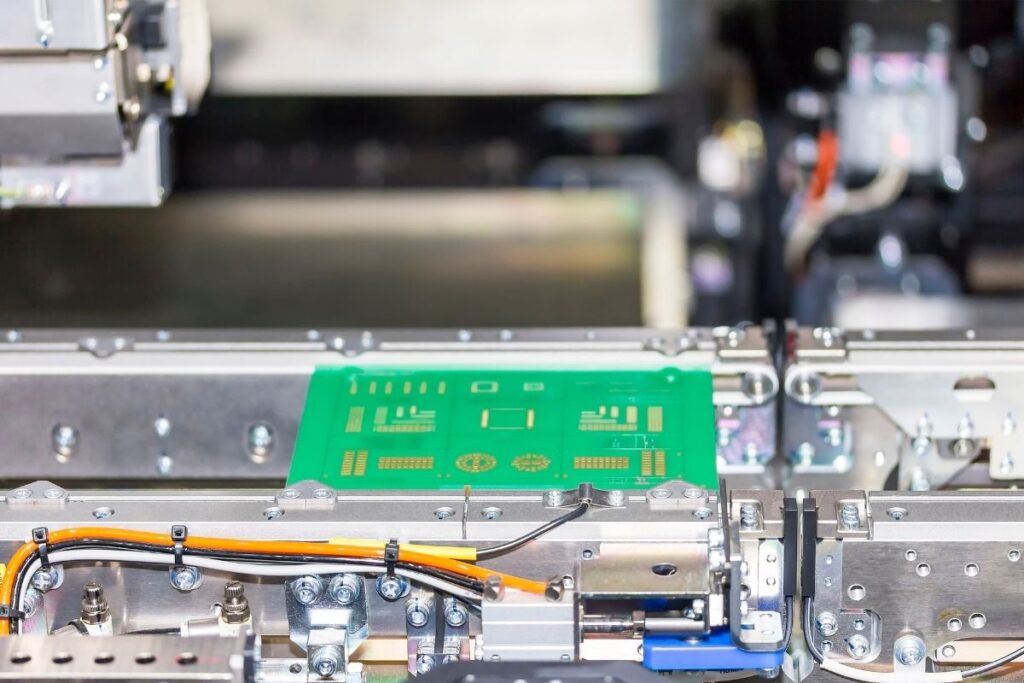

D450S高速ディスペンサー - ミクロンレベルの精度でLEDスクリーンの色差を克服

I. コアとなる利点:高精度スプレーと効率的な生産の完璧な統合

- 色差の根本原因を解決するミクロンレベルの精密制御

- XYZ3軸servo駆動システム(パナソニック製servoモーター+ボールネジ)を採用し、位置決め精度±0.02mm、繰り返し精度±0.02mmを実現。2~30mm幅のインクを高精度に塗布できるため、ピクセルピッチ≤0.9mmのLEDディスプレイといった超小型ピッチの用途に最適です。.

- 日本製SMCシリンダーと高精度霧化スプレーバルブを備え、空気圧レギュレータ(0.4~0.6MPa)の微調整により接着剤の量を安定的に制御し、PCBの背景に均一なインク塗布を確保して、基板の反射による色ずれを解消します。.

- 大規模ニーズに応える高速生産

- X/Y軸の最大移動速度は800mm/秒、Z軸は300mm/秒です。チェーン駆動搬送システム(速度2~5m/分)により、1時間あたり1,000枚以上のPCB塗布効率を実現し、LEDディスプレイの大量生産要件を満たします。.

- 自動浸漬グルーガン設計:ワークがないときは、グルーガンが自動的に浸漬して乾燥を防ぎ、接着剤の硬化やノズルの詰まりによるダウンタイムを削減し、稼働率を30%以上向上させます。.

II. インテリジェントシステム設計:ハードウェアからソフトウェアまで、プロセスの信頼性をフルに確保

- 優れた耐干渉性を備えた産業グレードのハードウェアアーキテクチャ

- 制御システム:Advantech産業用コンピューター+高速モーションコントロールカード。自社開発の塗布ソフトウェアを搭載し、軌跡プログラミングをサポートし、Windowsシステムと互換性があります。100以上のプロセスプログラムを保存でき、ワンクリックで様々なPCB塗布スキーム(COBモジュールとSMDパッケージの異なるパラメータなど)を呼び出すことができます。.

- フレーム構造: 80*60 mm 厚の角管を溶接 + 応力緩和処理し、剛性が強く、温度変形が小さい。作業台はガントリーフライス加工で水平にされ、ステンレス鋼保護プレートと静電粉体塗装が施されているため、耐腐食性があり、動作プラットフォームの安定性を確保します。.

- 操作の敷居を下げる人間工学に基づいた機能設計

- プログラミング方法:キーボードとマウスによる操作と軌跡ガイダンスをサポート。オペレーターはPCB部品の間隔に応じて異なるスプレーガンを選択し、部品の高さ(最大100mm)を自動調整できるため、専門エンジニアを介さずにパラメータ設定を完了できます。.

- 搬送システム: ブラシレス DC モーターが 25B タイプのステンレス チェーンを駆動し、幅は自動的に調整されます (50 ~ 450 mm)。インクによるチェーンの汚染を防ぐ保護ストリップが装備されており、さまざまなサイズの PCB (厚さ 0.5 ~ 4.0 mm) に適しています。.

III. LEDスクリーン製造の問題点を解決する技術的パラメータ

| 主要指標 | パラメータ | LEDスクリーンの色の違いに対する解決策 |

|---|---|---|

| 測位精度 | ±0.02 mm | ピクセルギャップの正確なインクカバレッジを保証し、均一な「仮想マスク」を形成して迷光クロストークをブロックします。. |

| コーティング厚さ制御 | 10~200μm | さまざまなインク粘度要件に適応し、コーティングの厚さの不均一性によって生じる反射の違いを回避します。. |

| 気圧安定システム | 0.4~0.6MPa微調整 | 接着剤量の一貫性を確保し、同じバッチの PCB の色偏差率を低減します。. |

| 目詰まり防止設計 | 自動浸漬グルーガン | ノズルの乾燥による噴射抜けを防ぎ、画面全体のインク色の均一性を確保します。. |

IV. アプリケーションシナリオ:小型ディスプレイからCOBパッケージまで、あらゆるシナリオに対応

- 小型ピッチLEDディスプレイ: PCBのピクセルギャップに黒インクを正確にスプレーして統合された遮光構造を形成し、P2.0以下のピッチの光散乱問題を解決し、コントラストを向上させます(ΔE<1)。.

- COBパッケージモジュール: チップ統合面にグラフィック インクをスプレーして、従来のマスクを置き換え、モジュールの継ぎ目の色の違いをなくし、放熱を最適化します (オプションの熱伝導性インク スプレー機能)。.

- フレキシブルスクリーンと特殊形状基板: PCBの5mm以上のエッジクリアランス制御をサポートし、アークおよびフレキシブル基板へのインクスプレーに適応し、LEDスクリーン(ウェアラブルディスプレイ、アーク広告スクリーンなど)の応用シナリオを拡張します。.

V. 結論:技術革新による色差ボトルネックの打破

D450S高速塗布機は、ミクロン単位の精密制御、産業グレードの安定性、そして柔軟な生産能力を備え、LEDディスプレイの色差を解決するための中核設備となっています。ハードウェアアーキテクチャからソフトウェアシステムに至るまで、フルチェーンの最適化により、高精度塗布の要件を満たすだけでなく、自動化設計による生産コストの削減も実現します。大規模な量産からカスタムR&Dまで、D450SはLEDスクリーンの色ムラを確実に保証します。.

カスタマイズされたソリューションについては今すぐお問い合わせください → 機器のデモンストレーションとプロセス検証 services の詳細については、ここをクリックしてください。.