記事

当社のブログで、表面実装、スルーホール、プリント基板実装技術などに関する率直な回答、役立つヒント、わかりやすい説明をご覧ください。

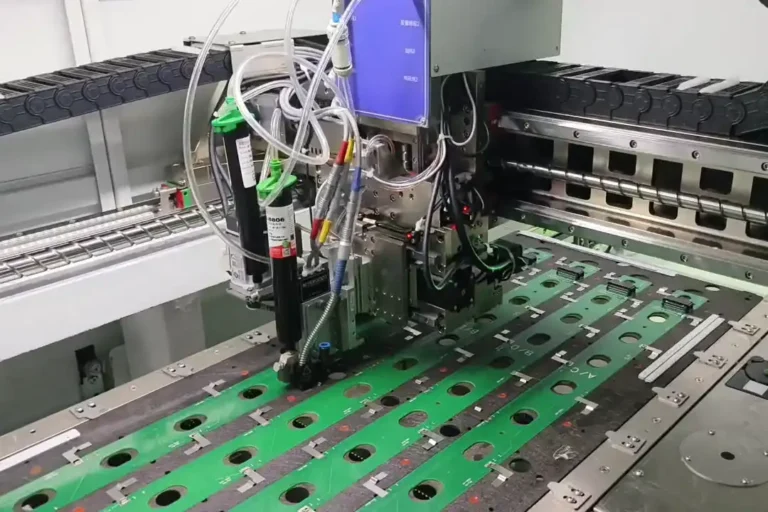

UV接着剤コンフォーマルコーティングプロセス仕様

1. PCBAにUV接着剤コンフォーマルコーティングを施すためのプロセスフローと要件を確立し定義する。コーティング機推奨機種:HC-P450S 機械パラメータを見るにはクリックしてください 2. 適用範囲 会社の全製品のPCBAのコンフォーマルコーティングプロセスに適用可能。 3. 内容 3.1 コーティング準備 コーティングするPCBAの目視検査を実施します。

高速精密ディスペンシングマシンD450S:LEDディスプレイの色差を解決するための中核機器

D450S高速ディスペンシングマシン - ミクロンレベルの精度でLEDスクリーンの色の違いを克服 I. コアの利点:高精度スプレーと効率的な生産の完璧な統合ミクロンレベルの精密制御で色の違いの根本原因に対処XYZ 3軸servo駆動システムを採用(パナソニックservoモーター+

LEDディスプレイ技術の進化:ディスペンシングマシンのインクジェット技術の革新に焦点を当てる

デジタル時代において、LEDディスプレイは多様な用途で重要な役割を果たしています。この記事では、ディスペンシングマシンにおけるインクジェット技術に焦点を当て、ディスプレイ開発の課題解決、均一な発光層の形成、SMT装置との相乗効果、そしてCOB/SMDパッケージのコントラストへの影響について考察します。また、LEDディスプレイのイノベーションにおける役割に焦点を当て、最適なインクジェットツールを推奨します。基本情報

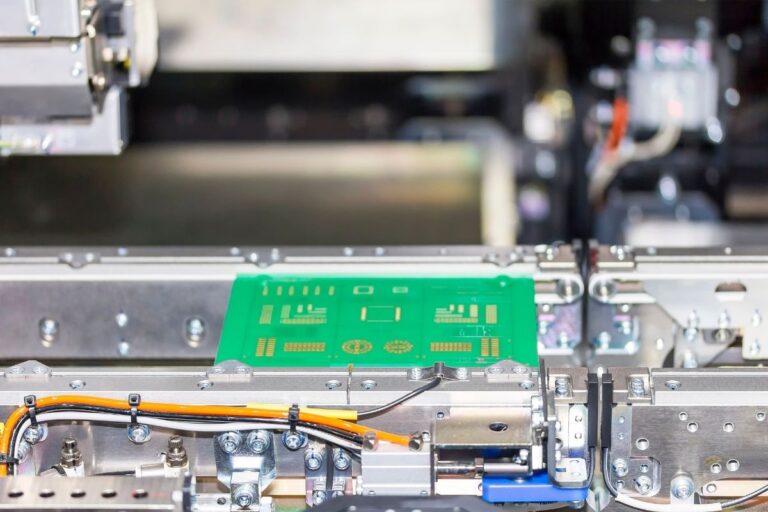

EVパワーバッテリーのCCS後処理向け高精度ディスペンシングマシンソリューション

I. 業界分析(生産現場にディスペンサーが必要な理由)最近の調査によると、新エネルギー車のパワーバッテリー向けFPCの需要が急増し、主要な成長ドライバーとして浮上しています。最新のデータによると、車載PCBにおけるFPCのシェアは12%から15%に増加しています。FPCの用途は、車両照明、ディスプレイモジュール、コア電源制御システム(BMS/VCU/MCU)、センサー、ADASなど多岐にわたります。,

保護への投資:選択的コーティングマシンのガイド

今日の熾烈な競争が繰り広げられるエレクトロニクス市場において、プリント回路基板アセンブリ(PCB)の信頼性と長寿命は極めて重要です。PCBは小型化、複雑化し、ますます過酷な環境で使用されるようになるにつれ、繊細な電子部品を湿気、埃、化学物質、そして極端な温度から保護することは、もはや贅沢ではなく、必需品となっています。そこでコンフォーマルコーティングが役立ちます。