II. ما هو CCS؟

![حل آلة التوزيع عالية الدقة لمعالجة CCS اللاحقة في بطاريات الطاقة الكهربائية 4 Teardown image of [product/model name] electronic module. Displays orange FPC interconnecting metallic cell - like components, critical for understanding internal design, component sourcing, and assembly process optimization.](https://haichensmt.com/wp-content/uploads/2025/06/CCS-1024x468.png)

محلول توزيع CCS (حالة موجودة):

محلول توزيع CCS

- غراء الأشعة فوق البنفسجية

يتم تطبيقه بشكل أساسي على صفائح النيكل على FPC لتعزيز وحماية نقاط اللحام. - غراء أصفر

يُستخدم لتثبيت المكونات الإلكترونية، مثل المحاثات والملفات والمحولات والمكثفات الإلكتروليتية والمستقبلات، مما يوفر الحماية والعزل للأجزاء الإلكترونية. في تقنية CCS، يُستخدم لتغليف المكونات الكهربائية وقطع الجهد العالي، ولطلاء بطاريات FPC المقاومة للرطوبة. - السيليكون الموصل للحرارة

صُممت لسد الفجوات بين مكونات توليد الحرارة وأجهزة التبريد، مما يُوسّع مساحة تلامسها لتعزيز التوصيل الحراري. يُبدّد هذا الحرارة بفعالية من المكونات الإلكترونية أثناء التشغيل. في تقنية CCS، تُستخدم مادة ser كمادة واجهة حرارية بين مصادر الحرارة (ترانزستورات الطاقة، الثايرستورات، عناصر التسخين، إلخ) وأجهزة التبريد (المشتتات الحرارية، شرائح التبريد، الأغطية، إلخ)، مما يُحسّن كفاءة تبديد الحرارة. - لاصق/مانع تسرب السيليكون

مناسب للتغليف والعزل ومقاومة اللهب في الوحدات الإلكترونية وأجهزة الاستشعار والمكونات، بالإضافة إلى ربط/تثبيت الأجزاء الإلكترونية والعزل بين المكونات.

ملخص:

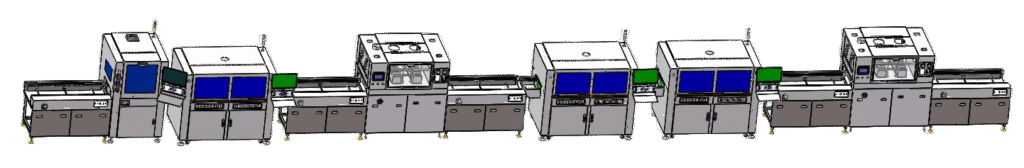

نظام التوزيع والتعبئة HC-D1200S من HaichenSMTs يتفوق هذا النظام في التطبيقات عالية الدقة والسرعة، حيث يتميز بطرق توزيع كمية بالتلامس وبدون تلامس. ويضمن إنتاج غراء موحدًا ودقة في القطع، مما يزيل عيوبًا مثل الترابط، وعدم تساوي حجم المادة اللاصقة، وتلف المكونات. ويعزز هذا النظام الإنتاجية وجودة المنتج بشكل كبير. وهو مزود بوحدات وظيفية متعددة الاستخدامات، مما يوفر تطبيقات مرنة، ويُعد الخيار الأمثل لمهام التوزيع والتعبئة الدقيقة.

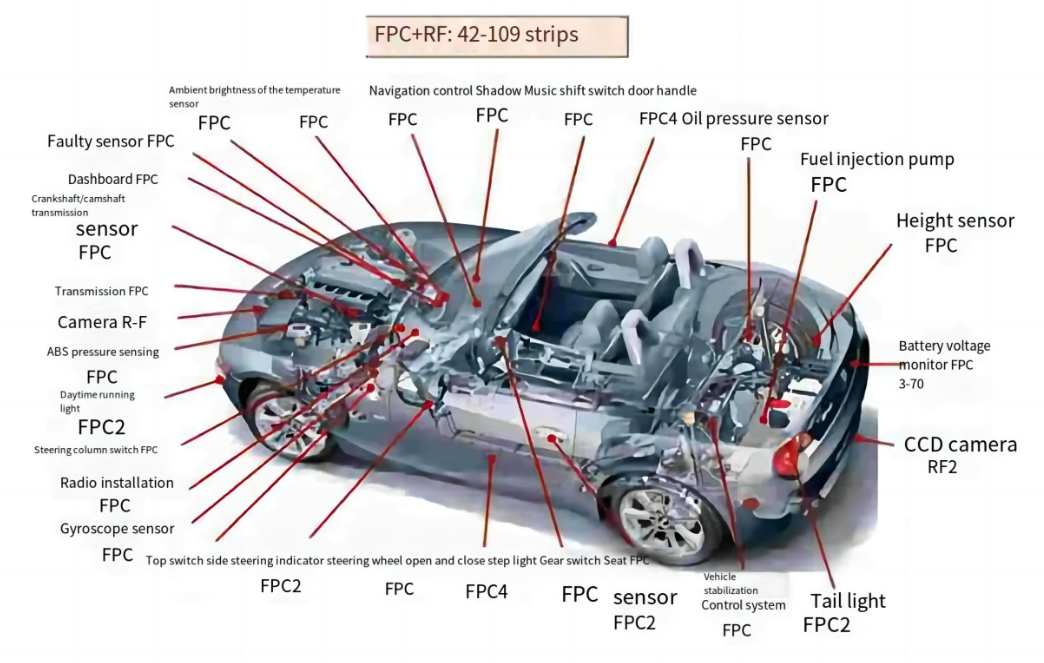

التطبيقات:

حشوة ناقصة

تغليف FPC

موصل FPC وتوزيع صفائح النيكل

توزيع الغراء الأحمر SMT

تغليف LED

تغليف المكونات

توزيع معجون اللحام

توزيع الغراء الأحمر/الأسود

طباعة نفث الحبر بشاشة ضيقة النطاق

تغليف أشباه الموصلات

تثبيت الرقاقة

عملية العمل: تحميل اللوحة ← ناقل إلى منطقة العمل ← وضع اللوحة ← المحاذاة البصرية ← التصوير الفوتوغرافي ← قياس ارتفاع Laser ← عملية التوزيع ← تفريغ اللوحة