Solutions

Haichen SMT Solutions

Custom SMT/THT/Coating/Assembly Solutions for Your Success

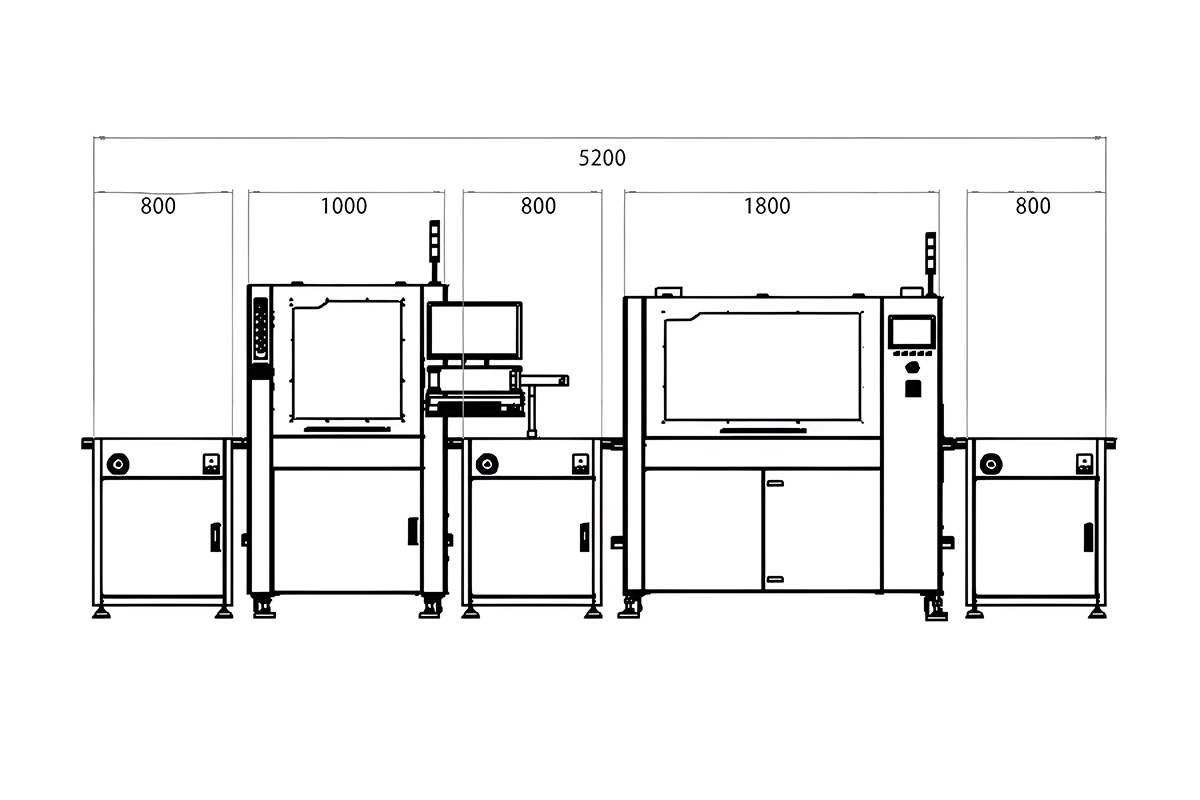

Cost-Saving One Man Operation Selective Conformal Coating Line

-Boost Productivity by 40% with Minimal Labor and Lowest Costs!

-1024x510.png)

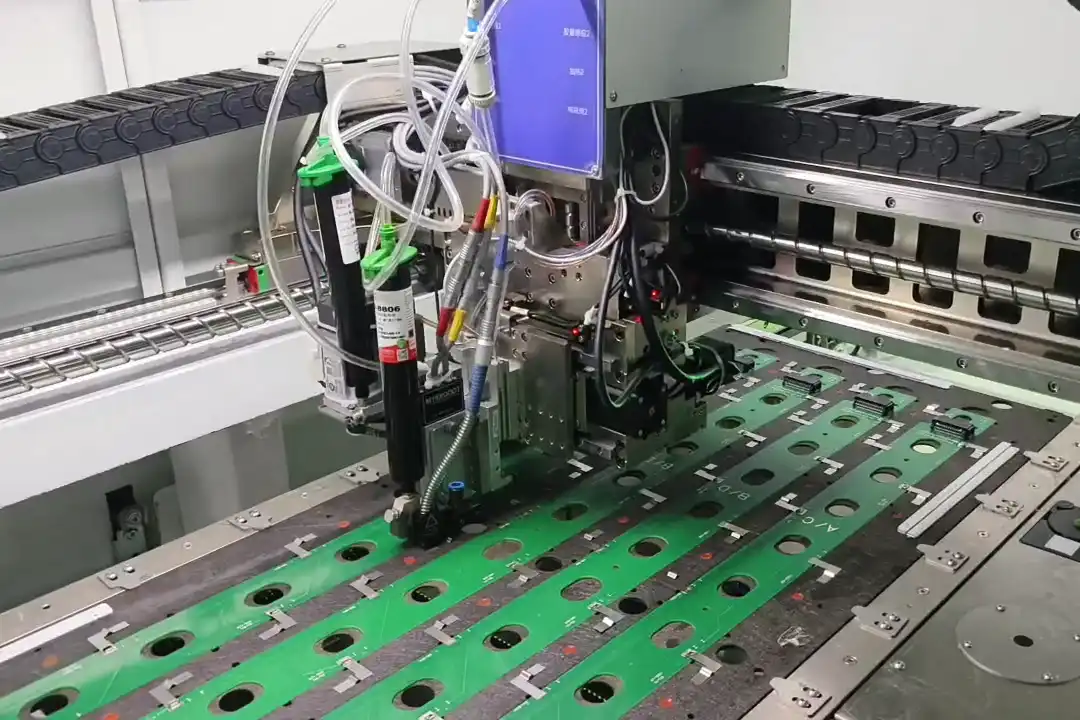

On-site shooting at customer’s factory

It only takes $21,000 to get this fully automatic coating line!(Standard configuration)

Work Flow of One man coating line:

The operator loads stacked PCBs into the Loader’s input tray, and the Loader auto – feeds them into the production line→

Selective conformal coating machine applies conformal coating to specific areas of PCBs based on pre – programmed patterns→

Conducts real – time quality checks to identify coating defects→

UV curing oven Hardens the conformal coating using ultraviolet (UV) light→

Automatically removes finished PCBs from the line and stacks them(Finish)

1. Program and test the coating path for accuracy.(within 20 mins)

2. Load PCBs into the Loader(30s).

3.Unload finished boards from the Unloader(1 min).

The conformal coating line achieves competitive advantages in efficiency, quality and cost through the following features:

Production Efficiency

High automation level: Minimal manual intervention (limited to loading and unloading);

Moderate seamlessness between equipment (only temporary pause during coating process).

Quality Control

High process precision: Path accuracy ( ±0.02mm repeatability), consistent coating thickness (compliant with IPC-A-610 standard);

Traceability: The production line can integrate with MES systems to record coating parameters (e.g., time, pressure), inspection data, operator information, etc., enabling full-process traceability.

Cost Optimization

Labor cost: Compared with traditional manual coating lines, this solution saves manpower (1 operator vs. 3–5 operators) and requires lower skill levels (easy-to-learn programming; no specialized background needed);

Material cost: Improved coating utilization (precision coating reduces material waste by 30%);

Maintenance cost: Low equipment failure rate (long MTBF), consumables replacement cycle (every 6 months), and fast after-sales support (24-hour remote response).

Flexibility and Adaptability

Product compatibility: Quick product changeover (changeover time <30 minutes), compatible with a wide range of PCBA sizes (50mm × 50mm to 450mm × 450mm) and different coatings (acrylic/silicone/urethane);

Scalability: Supports modular upgrades (e.g., AOI inspection, in-line rework stations, additional valves, CCD vision cameras, laser height measurement, workpiece heating modules, etc.) to meet future capacity or process requirements.

Safety and Compliance

Operational safety: Equipment includes safety features such as UV shielding in the curing oven, solvent leak alarms in the coating machine, and EMC compatibility to avoid interference with surrounding equipment.

This production line reduces manpower to just one operator through automated loading/unloading by Loader/Unloader units, cutting 2–4 positions compared to traditional lines. The Selective Coating Machine’s ±0.02mm positioning accuracy improves coating utilization by 40%, reducing under-coating and over-coating defects by 60%. The UV curing oven enables rapid curing in 1 minutes, shortening the cycle time to tens of seconds per PCBA and increasing production capacity by 40%… This delivers a competitive advantage in terms of efficiency, quality, and cost.

Our Process – How We Work with You

Consultation

We begin by understanding your production needs, challenges, and goals. Our experts work closely with you to evaluate your current processes and identify opportunities for improvement.

Solution Design

Based on your requirements, we design a tailored solution that incorporates the right mix of Haichen SMT equipment and technologies. We ensure that the proposed solution aligns with your production goals and budget.

Implementation

Our team supports you throughout the installation process, providing on-site assistance, training, and integration support. We ensure that your new equipment is up and running smoothly, minimizing downtime.

Ongoing Support

Our commitment doesn’t end with installation. We provide ongoing technical support, maintenance services, and training to ensure that your production line continues to operate at peak performance.

Why Choose Haichen

At Haichen SMT, we understand that choosing the right SMT equipment partner is crucial for your manufacturing success. As a leading provider of PCB coating and dispensing solutions, we combine technical expertise with customer-focused service to deliver exceptional value.

Expertise

With decades of experience in the SMT industry, we understand the challenges faced by PCB manufacturers.

Quality Guarantee

As an ISO certified company, We hold ourselves to the highest standards of quality, from product design and manufacturing to after-sales support.

Innovation

We strive to stay ahead of industry trends and deliver innovative products that help our customers lead in a competitive market.