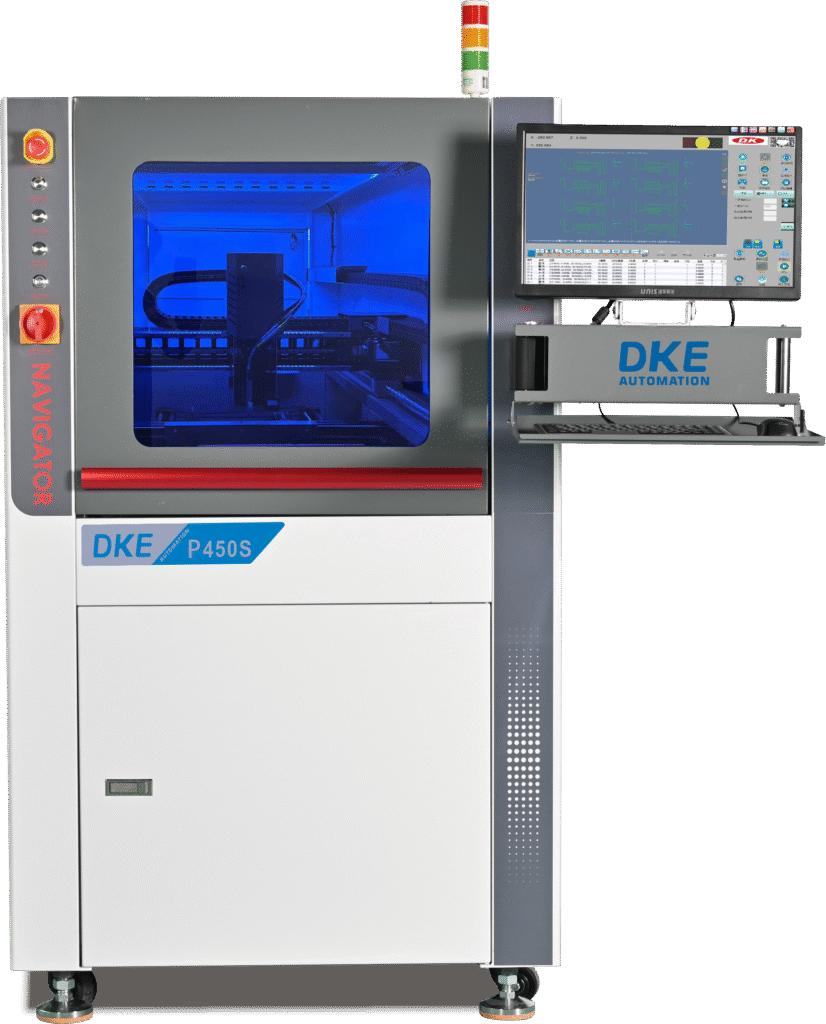

Selective Conformal Coating Machine P450S

The P450S Selective Conformal Coating Machine from Haichen is a high-precision solution for advanced coating applications. With a robust steel platform and Panasonic servo-driven linear modules, it ensures stability and reliability in high-speed operations. The fully sealed module protects against fog and corrosion, while the machine’s versatility in spot, linear, and curve spraying results in clear and uniform coating edges.

The P450S is equipped with automatic soaking and spitting devices, reducing glue jetting and blocking, making it ideal for high-density complex circuit board coating processes.

Key Features:

- Enhanced Stability: Integral steel platform for high-speed operation stability.

- Advanced Drive System: Panasonic servo + high-precision ball screw for precision.

- Fully Sealed Module: Protects against fog and corrosion for extended life.

- Versatile Coating: Achieves spot, linear, and curve spraying with clarity.

- Automatic Soaking and Spitting: Prevents glue jetting and blockage issues.

| 功能配置 Functional configuration | 技术参数说明 Technical parameters and description | 功能配置 Functional configuration | 技术参数说明 Technical parameters and description |

| 设备型号 Equipment model | P450S | 输送速度 Conveying speed | 0.8-15m/min |

| 外形尺寸 Overall dimensions | L=1050 D=1300 H=1600 | 输送轨道 Conveying rail | 专用铝合金轨道+不锈钢链 Special aluminum alloy rail+ Stainless steel chain |

| 设备重量 Equipment weight | 450kg | 宽度调整模式 Width adjustment mode | 自动+按钮式电动宽度调整 Automatic+Button-type electric width adjustment |

| 控制方式 Control mode | 工控机+运动控制卡 PLC+motion control card | 宽度调整速度 Width adjustment speed | 250mm/min |

| 运行软件 Operating software | Windows | PCB边缘空间 PCB edge space | ≥5mm |

| 编程方式 Programming mode | 示教/在线编程 Teaching/online programming | 传输马达功率 Transmission motor power | DC24V 69W*2 |

| 主轴数量 Number of axis | X,Y,Z | 通讯端口 Communication port | SM EMA连接器 SMEMA connector |

| 主轴驱动 axis drive | 伺服电机+滚珠丝杆 Servo motor +Ball screw | 单次涂覆宽度 Single coating width | 5~30mm |

| 涂覆行程 Coating travel | X:510mm Y:510mm | 设备气压 Equipment air pressure | 0.6Mpa |

| 胶阀数量 Number of valves | 双阀一字排列 Two-Valve Linear Arrangement | 排气量要求 Exhaust volume requirements | 15m³/min |

| 最大移动速度 Max.moving speed | 800mm/s | 设备电源 Equipment power supply | AC220V50~60HZ |

| 元件最大高度 Maximum height of component | ±90mm 90mm above and below the conveying surface | 设备总功率 Total equipment power | 2.2kw |

| 承重 Load bearing | 10kg | 标配功能 Standard function | LED紫外线检测灯 LED UV inspection lamp |

| 重复精度 Repeat accuracy | ±0.02mm | LED照明 LED lighting | |

| 轨道数量 Number of rails | 1 | 废液回收 Waste liquid recycling | |

| 输送高度 Conveying height | 900±20mm | 静电接口 Electrostatic interface | |

| 工作方向 Working direction | ■左→右(标准)□右→左 ■Left→right(standard)□Right→left | / |

Addressing Issues: High labor costs, insufficient productivity, poor coating quality, uneven thickness, and waste of coating materials.

Applicable fluids: Conformal coating, UV adhesive, acrylic-based, epoxy-based, silicone-based, and other coating products.

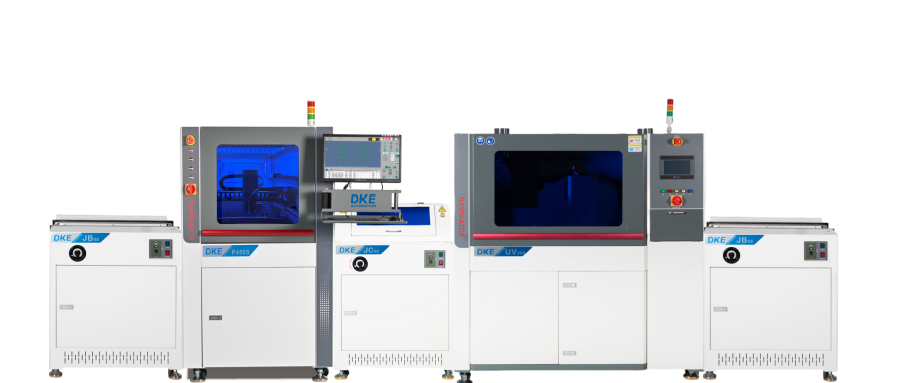

The equipment can be customized according to the product coating process requirements, the actual length of the factory production line, and the capacity demand.

Description

- Total Line Length: Approximately 5.2 meters

- Operators Required: 1-2 personnel

- Maximum PCB Size: 450 × 450 × H100 mm

- Track Width: 450 mm

- Single-side coating

Need Help Finding the Right Product?

Our team of experts is here to guide you in selecting the best solutions for your needs. Please feel free to reach us for support.